| Symptoms | reason | Countermeasures |

| Chuck cannot move | Parts of the chuck are damaged. | Disassemble the chuck and replace it |

| The sliding part is stuck. | Disassemble the chuck and take out the stuck part, repair or replace it with oilstone |

| The rotary cylinder stops working. | Check the oil pressure system, such as the pressure relief valve |

| The full stroke of the base jaw is insufficient | There are too many iron filings stored inside the chuck. | Clean up after decomposition |

| The tie rod is loose | Re-tighten the lever |

| There is slippage in the work | The clamping stroke of the base jaw is insufficient | Re-clamp the workpiece so that the position of the base jaw is at the midpoint of the stroke |

| Insufficient clamping force of the chuck | Check whether the oil pressure set by the lock is reached |

| The formed diameter of the upper jaw is different from the diameter of the workpiece | Redo it with the correct shaping method |

| Too much cutting force | Recalculate the cutting force and whether it meets the specifications of the chuck |

| Insufficient lubricant for base jaw lubrication | Relubricate the parts according to the lubrication process and then operate the chuck several times without the workpiece |

| Rotational speed is too high | Reduce the speed to the standard to reduce the influence of centrifugal force |

| poor precision | Chuck outer diameter deflection is too large | Correct the deflection of the outer diameter or end face and lock the screw |

| External factors intervene between the base jaw and the upper jaw, such as dust | Remove jaws and clean completely |

| The fixing screw of the upper claw is not locked | Lock with proper torque |

| Excessive clamping force deforms the workpiece | Reduce the clamping force to an appropriate level, so that the machine can clamp the workpiece without deformation |

| The height of the upper claw is too high, which deforms the upper claw or the fixing screw | Lower the upper jaw to standard height |

| Improper or imperfect process of forming upper jaw | To determine if the forming ring is properly placed, check the oil pressure and the surface roughness of the forming part of the upper jaw. |

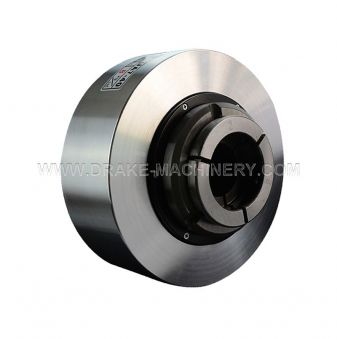

C Air Hydraulic Pressure Chuck Vice Claw

C Air Hydraulic Pressure Chuck Vice Claw  JAB High Speed Rotary Type Pneumatic Chuck

JAB High Speed Rotary Type Pneumatic Chuck  JAB-W25 Adjustable Precision High Speed Chuck

JAB-W25 Adjustable Precision High Speed Chuck  JAS Fixed Ultra Precision Diaphragm Chuck

JAS Fixed Ultra Precision Diaphragm Chuck  JAS Pneumatic Fixing Chuck

JAS Pneumatic Fixing Chuck  JA Ultra Precision Diaphragm Chuck

JA Ultra Precision Diaphragm Chuck  JA Pneumatic Rotary Quick Chuck

JA Pneumatic Rotary Quick Chuck  JB Spring Collet Back Pull Passive Chuck

JB Spring Collet Back Pull Passive Chuck